Difference between revisions of "HackTrack"

From Hackstrich

(Adding image link to CAD file of case) |

(Not involved with the lab anymore, cancelling this.) |

||

| (7 intermediate revisions by the same user not shown) | |||

| Line 3: | Line 3: | ||

== Ideas == | == Ideas == | ||

* Lots of switches and knobs to flip/dial, LEDs to blink | * Lots of switches and knobs to flip/dial, LEDs to blink | ||

| − | ** | + | ** 8 big toggle switches to identify which tasks you have completed |

** LEDs with each of these switches for ... something | ** LEDs with each of these switches for ... something | ||

** Space beside each toggle/LED for a written label identifying what the task is | ** Space beside each toggle/LED for a written label identifying what the task is | ||

| − | ** | + | ** One of the toggle switches will have an associated selector knob for an 'other' option, knob to specify minutes put into lab cleanup or something like that |

** 20x2 LCD screen for feedback and because I like LCD screens | ** 20x2 LCD screen for feedback and because I like LCD screens | ||

** Three large red/yellow/green LEDs to give feedback on something (mostly because someone suggested it would look cool) | ** Three large red/yellow/green LEDs to give feedback on something (mostly because someone suggested it would look cool) | ||

| Line 23: | Line 23: | ||

* ...found it was really big and the acrylic i wanted to use wasn't big enough | * ...found it was really big and the acrylic i wanted to use wasn't big enough | ||

* Redesigned front panel for the ProxPoint Plus that another member donated to the project | * Redesigned front panel for the ProxPoint Plus that another member donated to the project | ||

| + | |||

| + | === 2011-02-27 === | ||

| + | * Optimized G-code output for front/back panels, cut final versions of both (back in opaque white, front in transparent blue). | ||

| + | * Worked on a test of laser counterboring for the rotating selector switch nut (5 concentric circles at relatively low power repeated until enough material has vaporized) | ||

| + | ** Will do one more test next time, then counterbore the final panel | ||

| + | * Test fit the following: | ||

| + | ** Toggle switches - fit relatively well, nut doesn't have much to grab but works well enough I think | ||

| + | ** Small LEDs - tiny bit loose in the holes, will need to tack them in with a bit of CA or something | ||

| + | ** Large 'traffic light' LEDs - fit perfectly | ||

| + | ** HID Reader - fits perfectly | ||

| + | ** LCD - need longer bolts than I had at the lab, but fit looks good other than that | ||

| + | |||

| + | === 2011-03-05 === | ||

| + | * Tested laser counterboring a bunch, haven't done it on the final panel yet as I'm still tweaking it. | ||

| + | * Fit most other parts to the front panel including LCD. | ||

| + | * Started working on clock + data HID reader code for Arduino. | ||

| + | |||

| + | === 2011-03-06 === | ||

| + | * Finished clock + data HID reader code for Arduino | ||

| + | ** What a horrible protocol! | ||

| + | * Started working on Ethernet code for the system | ||

| + | ** Realized the LCD and Ethernet Shield both use the same I/O pins, doh! | ||

| + | * Designed the [[HackTrack Shield]] for the Arduino, which gives: | ||

| + | ** 40 digital I/Os via I2C | ||

| + | ** LCD port that can be connected directly to the Arduino or to the onboard I2C GPIOs | ||

| + | *** Includes contrast pot, backlight resistors, etc. | ||

| + | |||

| + | === 2011-03-13 === | ||

| + | * Finalized [[HackTrack Shield]], ordered parts and PCBs. | ||

| + | |||

| + | === 2011-05-24 === | ||

| + | * After major customs delays, boards and parts are here for the [[HackTrack Shield]] | ||

| + | * Assembled first [[HackTrack Shield]] and started writing code for it, seems to work | ||

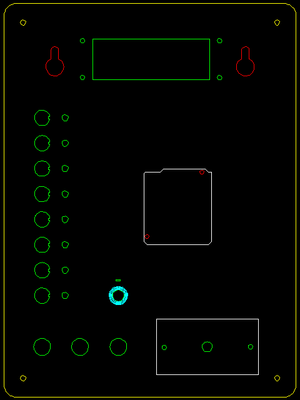

== Images == | == Images == | ||

| − | [[Image:HackTrack-ProxPoint-CAD.png|thumb|Design for acrylic case]] | + | [[Image:HackTrack-ProxPoint-CAD.png|thumb|none|Design for acrylic case]] |

| − | [[Category: | + | [[Category:Cancelled Projects]] |

| − | |||

Latest revision as of 15:05, 1 March 2017

HackTrack is going to be a system to keep track of who's been spending time cleaning the lab (HackLab.TO) and award points and such for doing so.

Contents

Ideas

- Lots of switches and knobs to flip/dial, LEDs to blink

- 8 big toggle switches to identify which tasks you have completed

- LEDs with each of these switches for ... something

- Space beside each toggle/LED for a written label identifying what the task is

- One of the toggle switches will have an associated selector knob for an 'other' option, knob to specify minutes put into lab cleanup or something like that

- 20x2 LCD screen for feedback and because I like LCD screens

- Three large red/yellow/green LEDs to give feedback on something (mostly because someone suggested it would look cool)

- HID reader to identify members

- Ethernet connection to send data to a message queue

- Arduino to tie everything together

- Acrylic front/back panels (as we can cut them on our lazzor), standoffs between them

Build Log

Before 2011-02-27

- Put basic design together

- Decided on the MiniProx HID reader that another lab member was going to be freeing up soon, designed front panel

- ...found it wasn't going to be freed up after all

- Redesigned front panel for the ProxPro HID reader that I had laying around

- ...found it was really big and the acrylic i wanted to use wasn't big enough

- Redesigned front panel for the ProxPoint Plus that another member donated to the project

2011-02-27

- Optimized G-code output for front/back panels, cut final versions of both (back in opaque white, front in transparent blue).

- Worked on a test of laser counterboring for the rotating selector switch nut (5 concentric circles at relatively low power repeated until enough material has vaporized)

- Will do one more test next time, then counterbore the final panel

- Test fit the following:

- Toggle switches - fit relatively well, nut doesn't have much to grab but works well enough I think

- Small LEDs - tiny bit loose in the holes, will need to tack them in with a bit of CA or something

- Large 'traffic light' LEDs - fit perfectly

- HID Reader - fits perfectly

- LCD - need longer bolts than I had at the lab, but fit looks good other than that

2011-03-05

- Tested laser counterboring a bunch, haven't done it on the final panel yet as I'm still tweaking it.

- Fit most other parts to the front panel including LCD.

- Started working on clock + data HID reader code for Arduino.

2011-03-06

- Finished clock + data HID reader code for Arduino

- What a horrible protocol!

- Started working on Ethernet code for the system

- Realized the LCD and Ethernet Shield both use the same I/O pins, doh!

- Designed the HackTrack Shield for the Arduino, which gives:

- 40 digital I/Os via I2C

- LCD port that can be connected directly to the Arduino or to the onboard I2C GPIOs

- Includes contrast pot, backlight resistors, etc.

2011-03-13

- Finalized HackTrack Shield, ordered parts and PCBs.

2011-05-24

- After major customs delays, boards and parts are here for the HackTrack Shield

- Assembled first HackTrack Shield and started writing code for it, seems to work